The Nanomechanics Group

|

Univ. Prof. Enrico Gnecco (group leader)

|

Dr. Hesam Khaksar (postdoctoral researcher)

|

|

Dr. Paolo Nicolini (FZU Prague, co-investigator)

|

Pawel Koczanowski (master student)

|

Dominik Zegarmistrz (master student)

The goal of our research is to understand the physics governing mechanical processes such as friction, wear and adhesion down to the atomic scale and, related to that, the driven motion of molecules and metal clusters on solid surfaces. This is made possible by the combination of advanced microscopy techniques such as AFM, SEM and TEM with modelling work and numeric simulations performed in collaboration with several groups. This research line, which is fundamental in nature, has a broad range of applications ranging from solid lubrication to sensorics. It may also help to understand and mitigate environmental problems such as the nucleation and release of nanoplastics out of solid surfaces damaged by abrasive wear.

Early stages of abrasive wear on amorphous materials

The formation of surface reliefs on compliant surfaces scratched by a rigid tip is explained by the competition between the driving elastic force and the plastic response of the material. Numeric simulations based on a model introduced in 2015 have been found in excellent agreement with AFM scratch tests performed on polymer surfaces. Similar phenomena were also studied on brittle materials, where a simple quantitative relation between stick-slip motion and the velocity-dependent periodicity of the structures formed on the scratched surfaces can be derived. Related to these processes, we are also investigating, both experimentally and theoretically, the detachment of nanoplastics out of repeated nanoscratch tests and the influence of the geometry of the damaged region on the morphology of the wear patterns.

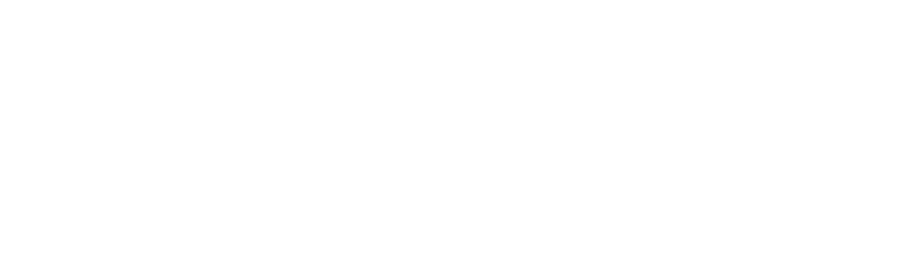

Rippling and nanoparticle formation on a polymer blend surface

repeatedly scraped by a silicon nanotip [H. Khaksar et al., Wear 536-537, 205160, 2024]

Early stages of abrasive wear on layered materials

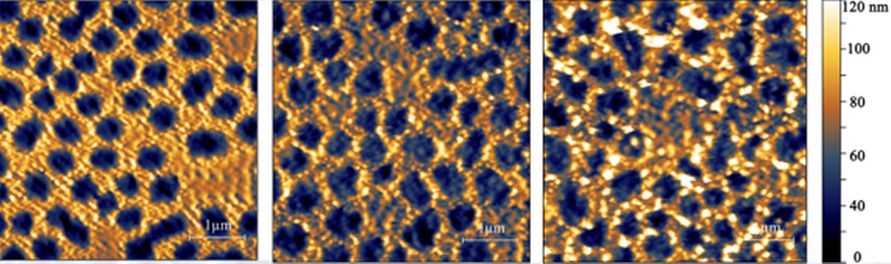

Controlled nano-scratching of layered materials leads to very different results. The folding and chipping mechanisms accompanying nanoscratch tests on graphene and transition metal dichalcogenide (TMD) surfaces can be explained by energetic considerations. As a next step, we aim to shed light on the relations between crystal orientation, scratch direction and other parameters such as the loading force and number of layers forming the surface. This is important in view of applications of these materials as protective coatings and solid lubricants e.g. in aeromotive industry.

SEM images of a MoS2 monolayer previously scratched by a diamond nanotip

[A. Özogul et al., Phys. Rev. Materials 4, 033603, 2020]

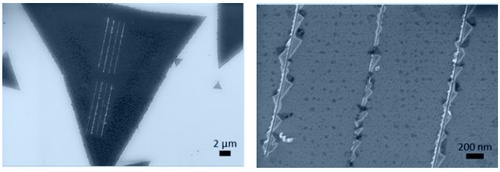

Molecular-scale friction in liquid environments

The absence of capillary condensation makes lattice resolved AFM images of sliding friction on crystal surfaces easier to achieve when the probing tip is completely immersed in water, as compared to ambient atmosphere. We aim to extend these studies to different liquid environments such as alcohols and ionic liquids. The ultimate goal is to shed light on the intricate relations between the stick-slip motion of the probing tip, the surface potential modified by the hydration layers and the damping forces limiting the slip distance.

ateral force maps of calcite, graphene on copper, Cu-phthalocyanines on dolomite and organic semiconductor crystals as imaged by atomic force microscopy [Vilhena et al., ACS Nano 2016; Nita et al., Nanotechnology 2014; Pimentel et al., J. Phys.: Condens. Matter 2016]

Nanotribology in ultrahigh vacuum

We are also involved in long-term collaborations with different groups studying nanomanipulation of polymer chains, contact modifications on the nanoscale, atomic-scale sliding friction, and the interpretation of these phenomena based on the Prandtl-Tomlinson and Frenkel-Kontorova models and molecular dynamics simulations. Related to this subject is the investigation of the friction between metal clusters and solid lubricant surfaces with different degrees of commensurability.

Selected Publications

1) E. Gnecco, A. Janas, B. R. Jany, A. George, A. Turchanin, G. Czempura, A. Kruk, M. Tripathi, F. Leed, A. B. Dalton, F. Krok, Atomic-scale characterization of contact interfaces between thermally self-assembled Au islands and few-layer MoS2 surfaces on SiO2, App. Surf. Sci. 616 (2023) 156483

2) Z. Liu, J. G. Vilhena, A. Hinaut, S. Scherb, F. Luo, J. Zhang, T. Glatzel, E. Gnecco, E. Meyer, Moiré-Tile Manipulation-Induced Friction Switch of Graphene on a Platinum Surface, Nano Lett. 23 (2023) 4693

3) J.J. Mazo, P.J. Martínez, P.Pedraz, J.Hennig, E.Gnecco, Plowing-induced structuring of compliant surfaces, Phys. Rev. Lett. 122 (2019) 256101

4) J.J. Mazo, D. Dietzel, A. Schirmeisen, J.G. Vilhena, E. Gnecco, Time strengthening of crystal nanocontacts, Phys. Rev. Lett. 118 (2017) 246101

5) S. Kawai, A. Benassi, E. Gnecco, H. Söde, R. Pawlak, X. Feng, K. Müllen, D. Passerone, C.A. Pignedoli, P. Ruffieux, R. Fasel, E. Meyer, Superlubricity of graphene nanoribbons on gold surfaces, Science 351 (2016) 957

6) J.G. Vilhena, C. Pimentel, P. Pedraz, F. Luo, P. A. Serena, C. M. Pina, E. Gnecco, R. Pérez, Atomic-scale sliding friction on graphene in water, ACS Nano 10 (2016) 4288

7) P. Pedraz, R. Wannemacher, E. Gnecco, Controlled suppression of wear on the nanoscale by ultrasonic vibrations, ACS Nano 9 (2015) 8859

8) M. Kisiel, E. Gnecco, U. Gysin, L. Marot, S. Rast, E. Meyer, Suppression of electronic friction on Nb films in the superconducting state, Nature Materials 10 (2011) 119

9) A. Socoliuc, E. Gnecco, S. Maier, O. Pfeiffer, A. Baratoff, R. Bennewitz, E. Meyer, Atomic-scale control of friction by actuation of nanometer-sized contacts, Science 313 (2006) 207

10) E. Gnecco, R. Bennewitz, T. Gyalog, Ch. Loppacher, M. Bammerlin, E. Meyer, H.J. Güntherodt, Velocity dependence of atomic friction, Phys. Rev. Lett. 84 (2000) 1172